产地:

规格:流 量:0.1-200m3/h 系统压力:0.1-1.2MPa 转 速:100-720r/min 功 率:0.12-185KW 进出口径:10-200mm 粘 度:1-1000000cp

公司所在地:上海上海

电话:86-021-69519069

进口凸轮转子泵(欧美进口品牌)的简单介绍进口凸轮转子泵又称胶体泵、凸轮泵、三叶泵、万用输送泵等,转子泵属于容积泵,输送流量可以较精确的控制也可方便地制成变量泵。进口凸轮转子泵(欧美进口品牌)的详细信息英国GRIMM格林进口凸轮转子泵 UK GRIMM Inlet cam rotor pump

英国GRIMM格林进口凸轮转子泵概述: 进口凸轮转子泵又称胶体泵、凸轮泵、三叶泵、万用输送泵等,转子泵属于容积泵,输送流量可以较精确的控制也可方便地制成变量泵。此泵的转速很低,一般在200rpm至600rpm之间,被输送的物料被平稳地输出而其成份不会受到破坏。可用于输送粘度很高的物质也可以方便地制成输出压力较高的品种。根据客户管道连接方式的需要,可做成上进下出型转子泵,根据客户安装方式及生产的需要,可做成移动型转子泵,根据客户调节转速及流量的需要,可做成变频调速型转子泵。 英国GRIMM格林进口凸轮转子泵特点: 1、本泵中凡与输送物料接触的零配件,均采用符合卫生标准的不锈钢材料制作,其密封件均采用无毒橡胶。可靠的防锈性和无毒密封性确保了安全卫生。 英国GRIMM格林进口凸轮转子泵应用领域: 日用化工:AES、LAS、AOS、K12、甘油、山梨醇、脂肪醇、沐浴露、护肤霜、洗发液、洗手液、牙膏、肥皂、洗衣粉料浆等。 UK GRIMM Inlet cam rotor pump summary: Imported cam rotor pump, also known as colloid pumps, cam pumps, three leaf pumps, pumps and so on, the rotor pump is a displacement pump, the flow can be more accurate control, but also can be easily made variable pump. The speed of the pump is very low, generally between 200rpm to 600rpm, the transported material is smoothly output, and its components will not be damaged. The utility model can be used for conveying materials with high viscosity, and can also conveniently produce varieties with higher output pressure. According to the needs of customers pipe connection, can make progress under the rotor pump, according to the needs of customers installation and production, can be made into a mobile type rotor pump, according to the needs of customers and the speed of flow regulation, can be made into a variable speed rotary pump. The rotor pump relies on two simultaneous, reverse rotating rotors (2 to 4 teeth) to generate suction (vacuum) at the inlet during the rotation so as to absorb the material to be conveyed. The two rotor divides the rotor chamber into a few small spaces and runs in the order of a, B, D, C. To the position of a running, only one room filled with medium; to position B, B encloses part of the medium; to the position of C, A in the room also closed to the media; the position of D, A room B chamber and the two chamber, the medium is transported to the discharge port. In this way, the medium (material) is transported continuously. The rotor pump adopts the whole shaft assembly, so that smaller size (the length can be shortened 100-250mm), to reduce the area, compact structure, coated with stainless steel, mirror polished, beautiful appearance, high grade, avoid dropping original paste paint. Performance Optimization: the overall assembly of the axle reduces the power consumption, noise and wear and tear of the elastic couplings, improves efficiency, achieves the highest efficiency, minimum internal sliding and longer service life. Rotors of different shapes have different effects, and are divided into the following categories: Blade rotor: suitable for conveying medium containing large particles of material, the crushing rate of large particles of material is low, but its large fluctuations, low pressure, small volume, rarely used. Two blade rotor: suitable for conveying medium and small particles of materials, the crushing rate of small and medium-sized materials is relatively low, slightly pulsating, less volume than the trefoil rotor. Three blade rotor: General rotor type, the volume is greater than other types of rotor, various performance indicators better than a blade, two blade rotor, but in the process of conveying materials, the particle material has a certain rate of fragmentation. Transmission options: 1.Motor + fixed ratio reducer: this way of transmission is simple, the rotor speed constant, that is to determine the flow of non adjustability. 2.Motor + mechanical friction CVT: the transmission speed by manual adjustment to achieve, it is safe and reliable, large torque, flow rate is adjustable, drawback of non automatic adjustment, more trouble, control in the process of operation, not in the shutdown state governor, referring to the use of maintenance the manufacturer's instructions. 3.Frequency conversion motor + frequency converter: this method can realize the automatic adjustment of speed, that is to realize the stepless speed regulation of flow. The utility model has the advantages of high degree of automation, low speed large torque converter, disadvantage is the higher prices, the use of maintenance according to the manufacturer's instructions. UK GRIMM Inlet cam rotor pump features Characteristic: 1.The pump and the delivery of materials contact parts and components, are in line with the hygiene standards of stainless steel materials, the seals are non-toxic rubber. Reliable rust prevention and non-toxic sealing, to ensure safety and health. 2.The flow structure of the rotor and the rotor chamber without dead center and non-metallic parts, to avoid the transport of material pollution. 3.Suitable for on-site CIP cleaning and steam disinfection, fully comply with the requirements of the United States FDA specification and pharmaceutical grade (GMP) specifications. 4.Especially suitable for conveying in the process of easy foam, and the delivery of high viscosity, concentration and any particle containing medium, the material transported by it to maintain the original quality unchanged, without any physical and chemical reaction. 5.Adopt external dynamic and static ring mechanical seals, which can be directly washed by water. It is resistant to high pressure, difficult to wear and no leakage. 6.Small size, large flow, high head pressure, suitable for long distance and high resistance quantitative transportation. 7.The impeller of the pump is separated from the drive gear, and a certain gap is ensured between the spare parts of the pump cavity, and the utility model has the advantages of no contact, no wear, low noise, good reliability, long service life, energy saving and consumption reduction. 8.After the configuration of frequency converter, you can freely adjust the flow, and can be used as a general metering pump. 9.Can transport steam, liquid, solid and other three-phase mixed material. The viscosity of the medium to be transported can be 1000000CP high and a slurry containing 55% solids. 10.Compact structure, easy maintenance, almost no wearing parts, low operating costs. 11.It not only has the characteristics of the general rotary pump, but also has some advantages in conveying high viscosity and large particles containing material, and it can also transport the material with very thick material. The material transported by it keeps the original quality unchanged. UK GRIMM Inlet cam rotor pump technical parameters: Flow rate: 0.1-200m3/h System pressure: 0.1-1.2MPa Speed: 100-720r/min Power: 0.12-185KW Inlet & Outlet: 10-200mm Viscosity: 1-1000000cp Seal: A: mechanical seal B: water-cooled mechanical seal Material: carbide, silicon carbide, silicon nitride, graphite, ceramics, etc. C: packing seal Material: polytetrafluoroethylene fiber, carbon fiber, graphite core, carbon fiber and so on Material: 304, 304L, 316, 316L Mode of work: intermittent, continuous Connection: flange, thread, clamp Installation: fixed type, mobile type UK GRIMM Inlet cam rotor pump applications: Daily chemical industry: AES, LAS, AOS, K12, glycerol, sorbitol, fatty alcohol, bath lotion, skin cream, shampoo, soap, toothpaste, soap, washing powder slurry etc.. Fine chemical dye, pigment, various pulp, chemical additives, adhesives, rubber, leather, 104 silicone oil, a variety of materials such as colloid emulsion explosive. Food: chocolate, milk, yogurt, honey, syrup, sucrose, Tomato Juice, concentrated juice, jam, ice cream, milk, yeast mud, meat pulp, jelly, yogurt, spices, alcohol, soy protein, flour paste etc.. Paper: polyacrylamide (PAM), calcium carbonate, starch paste, carboxylated styrene butadiene/styrene acrylic latex, rosin, rosin, pulp, filler, dry strength agent, wet strengthening agent, sizing agent, retention agent, defoaming agent, coating, water treatment chemicals etc.. Chemical fiber: sticky mucilage porridge, PVA, PVA slurry, slurry, slurry, acrylic amine aramid polyester and polyester, polypropylene fiber, synthetic fiber, functional fiber etc.. Medicine: all kinds of ointment, extract, medicine emulsion, pills, paste, syrup, health care products, drugs and so on. Paint: paint, coating, printing ink, insulating paint, resin, auxiliary agent, organic solvent, etc. |

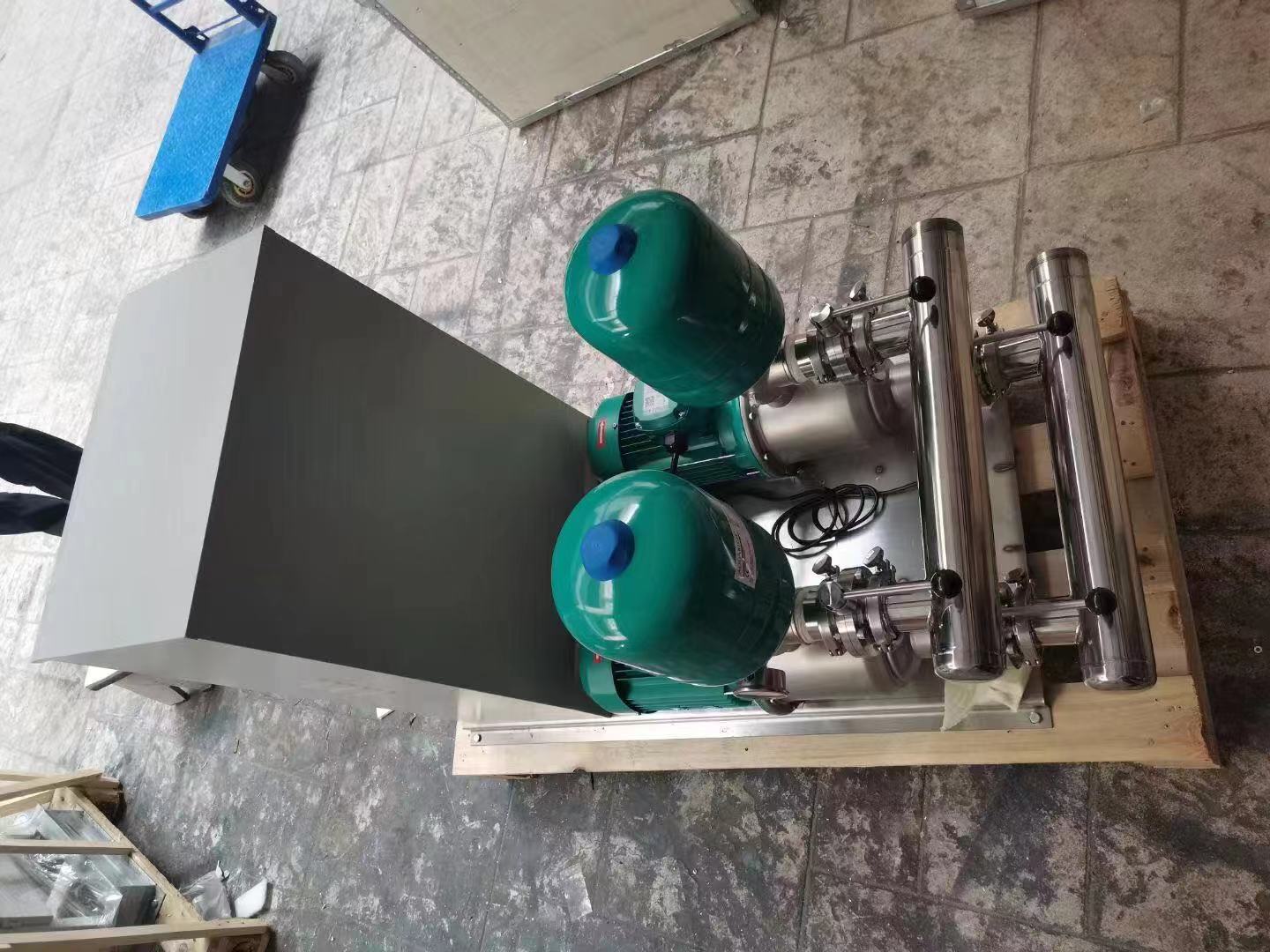

- 福建格莱富楼层增压无负压供水设备

- 德国原装Schwarzer微型泵

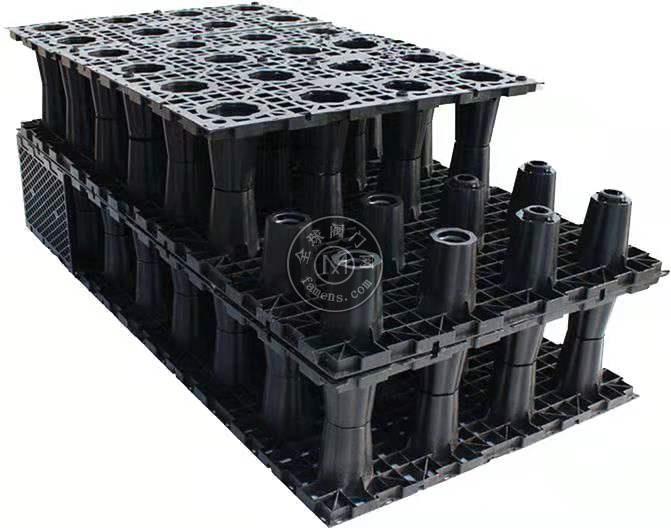

- 厦门雨水收集系统

- 安溪厂家生产自吸排污泵 高吸程自吸泵

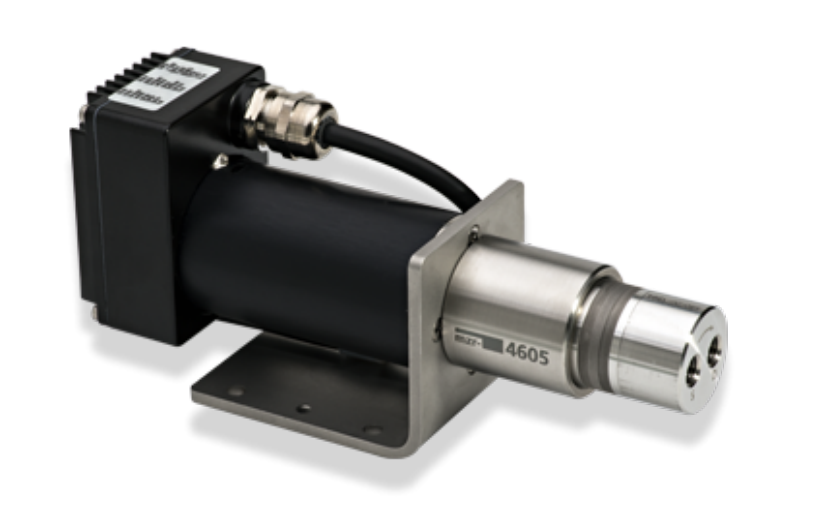

- 清洗剂和催化剂的精密添加HNPM微量泵mzr-4605

- HNPM mzr-4605微量泵用于汽油微量添加

- 胶黏剂输送HNPM微量泵mzr 2505

- 高粘度润滑脂输送HNPM微量泵mzr-7243

- 成型油输送HNPM mzr-2521 微量泵

- HNPM化学应用系列 mzr-6355微量泵

- 厦门雨水收集系统要注意什么

- 跨境直销Osip高低压颗粒状杂质外围设备 水泵厂家批发

- 德国采购RENA泵-德国赫尔纳(大连)公司

- BERTOLINI泵---德国赫尔纳(大连)销售

- 漳州不锈钢自吸泵 卧式耐腐蚀化工自吸离心泵

- 湖里不锈钢自吸泵 卧式耐腐蚀化工自吸离心泵

- 云霄不锈钢自吸泵 卧式耐腐蚀化工自吸离心泵

- 漳浦不锈钢自吸泵 卧式耐腐蚀化工自吸离心泵

- 东山厂家生产大流量中央空调循环管道泵

- 同安厂家生产大流量中央空调循环管道泵

- 泉州厂家生产大流量中央空调循环管道泵

- 三明厂家生产大流量中央空调循环管道泵

- 福州厂家生产大流量中央空调循环管道泵

- 沙县厂家生产大流量中央空调循环管道泵

250996786

250996786