详细信息

G3系列固定球阀-Trunnion Ball Valve的简单介绍三片式阀体设计 进口和出口 双阻塞泄放功能 大枢轴或枢轴板设计,确保球体在高压下具有正确的中心位置,保证阀门良好的操作性能G3系列固定球阀-Trunnion Ball Valve的详细信息主要设计特点-Main Designing Features

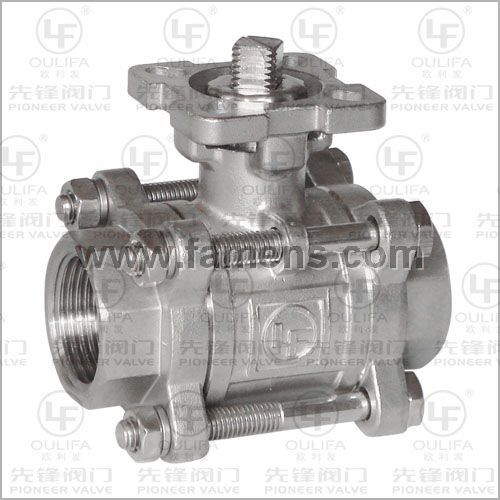

· 三片式阀体设计

Three pieces body design

· 进口和出口双向密封功能

Seal on up-stream and down-stream sides of valve

· 双阻塞泄放功能

Double block and bleed function

· 大枢轴或枢轴板设计,确保球体在高压下具有正确的中心位置,保证阀门良好的操作性能

A large trunnion or trunnion support design ensures central position of ball under the highest working pressure. This permits ease of operation.

· 球体与阀杆有效接触,性能优越的防静电装置

Grounding device for positive anti-static contact between ball / stem and body

· 2组O型密封圈,加上阀杆上的防火填料结构,可有效防止泄漏

Two set of O-ring seals plus fire-safe packing on the stem efficiently prevent leakage

· 密封剂注入器设计,可在紧急状态下注入密封胶,对阀杆或阀座进行密封

Sealant injection fittings for emergency stem or seat sealing

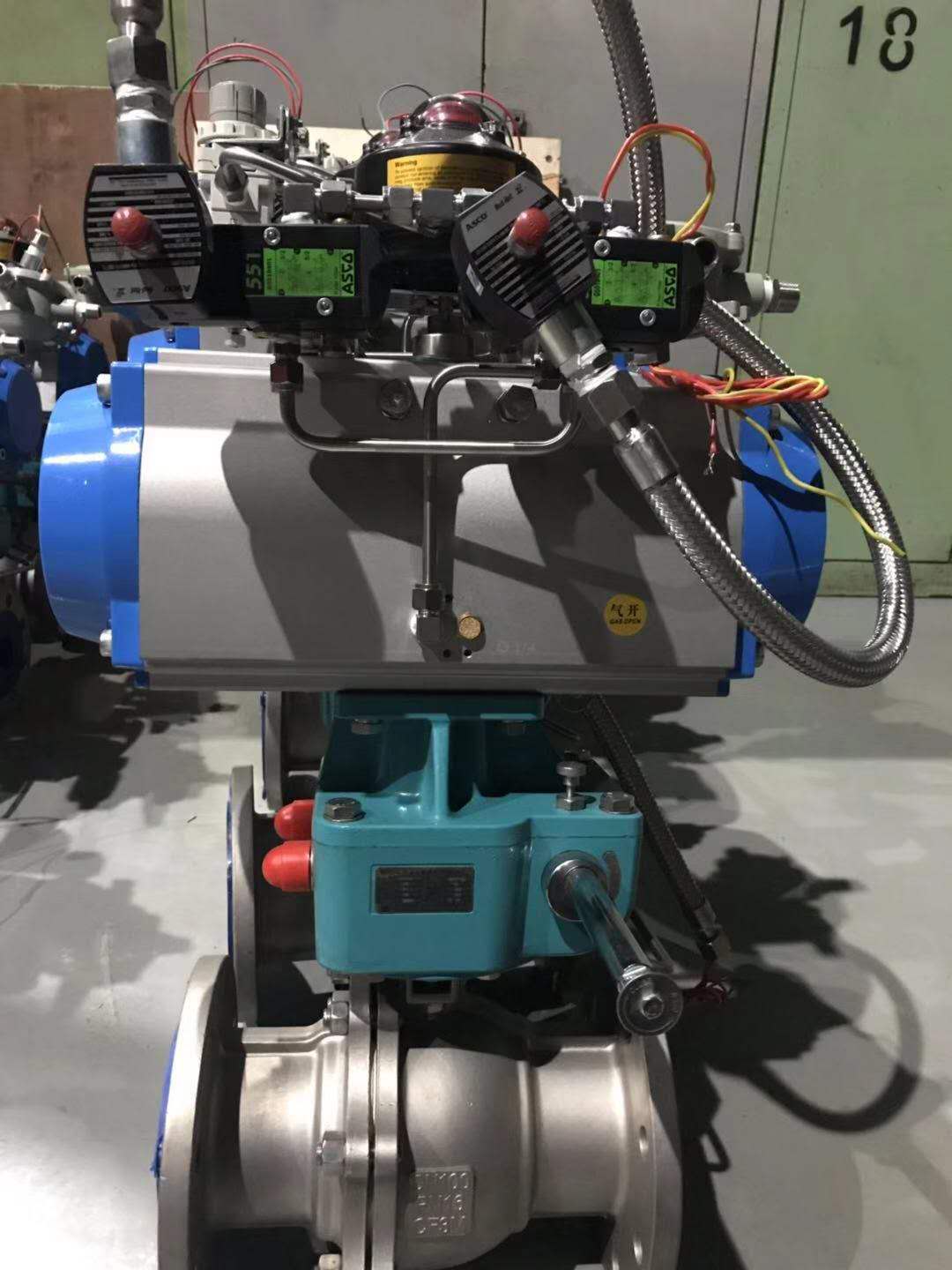

· 预置驱动装置平台及螺栓孔,可随时装配驱动装置

Actuator mounting surface are machined and drilled, ready for mounting actuator

· 可选择的防火功能

Optional fire-safe function

· 符合NACE规范要求

All ball valves can be supplied in full compliance with NACE MR0175 Standard.

· 带弹簧的浮动阀座设计

A floating seat with spring design is provided.

·低压时阀座在弹簧预紧力的作用下,保证球与阀座间的低压密封

The preload of spring ensures bubble-tight sealing of ball and seat at low pressure.

·高压时阀座唇与球体全面接触,确保阀门的可靠密封性和较低的操作扭矩

At high pressure, the seat lip deflects slightly to ensure full seat-to-ball contact. This results in reliable sealing at high pressure and low operating torque.

主要零件标准材料规范 Standard Material Specification for Main Parts

|

我要询价

推荐产品

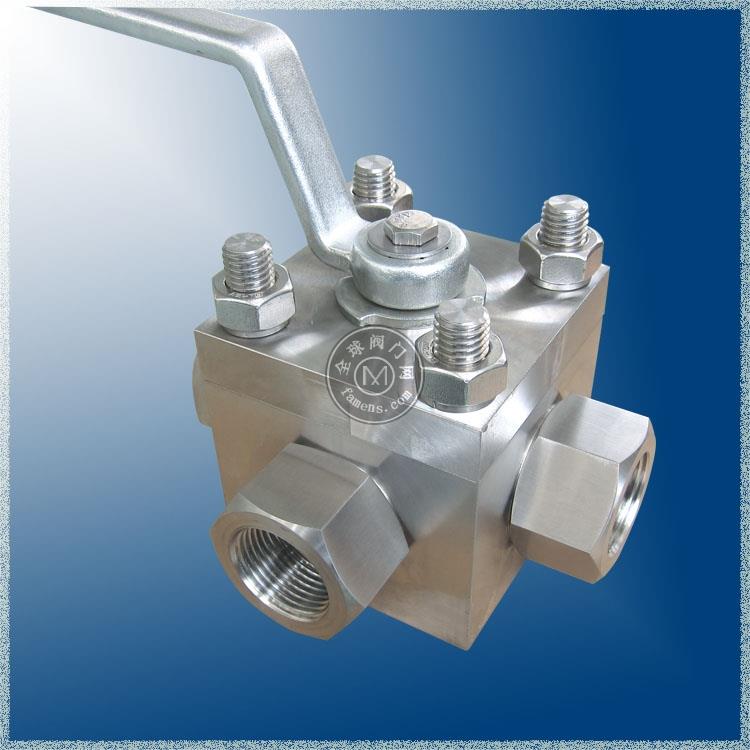

- Q14/15F内螺纹三通球阀

- 法兰三通球阀、T型三通球阀、L型三通球阀

- Q641F46-16P气动不锈钢衬氟球阀

- KP7015 数控球体磨床

- 高压L型换向球阀

- 3PC高平台内螺纹球阀

- 水利球阀

- 上海北麦Q41F不锈钢球阀

- GEROYAL 电动塑料球阀PPH法兰连接软密封耐酸碱耐腐蚀阀门厂家

- 供应京牌热力球阀,京牌热力球阀Q967F,北京市阀门总厂股份有限公司热力球阀Q967F

- 冷冻机组 低温不锈钢球阀DQ41

- 法兰球阀

- 电动 全衬 半衬 耐磨 陶瓷 球阀

- 微型电动球阀

- 京牌 球阀

- AT气动球阀法兰Q641F-16铸钢不锈钢高温蒸汽快速切断开关三通V型

- 浮动球阀

- KP7025 数控球体磨床

- 北京市阀门总厂 气动球阀

- PVC气动球阀

- 美标球阀Q345Y

- 气动球阀

- 手动固定球阀

- Q41F/PPL法兰浮动球阀

19160434

19160434