详细信息

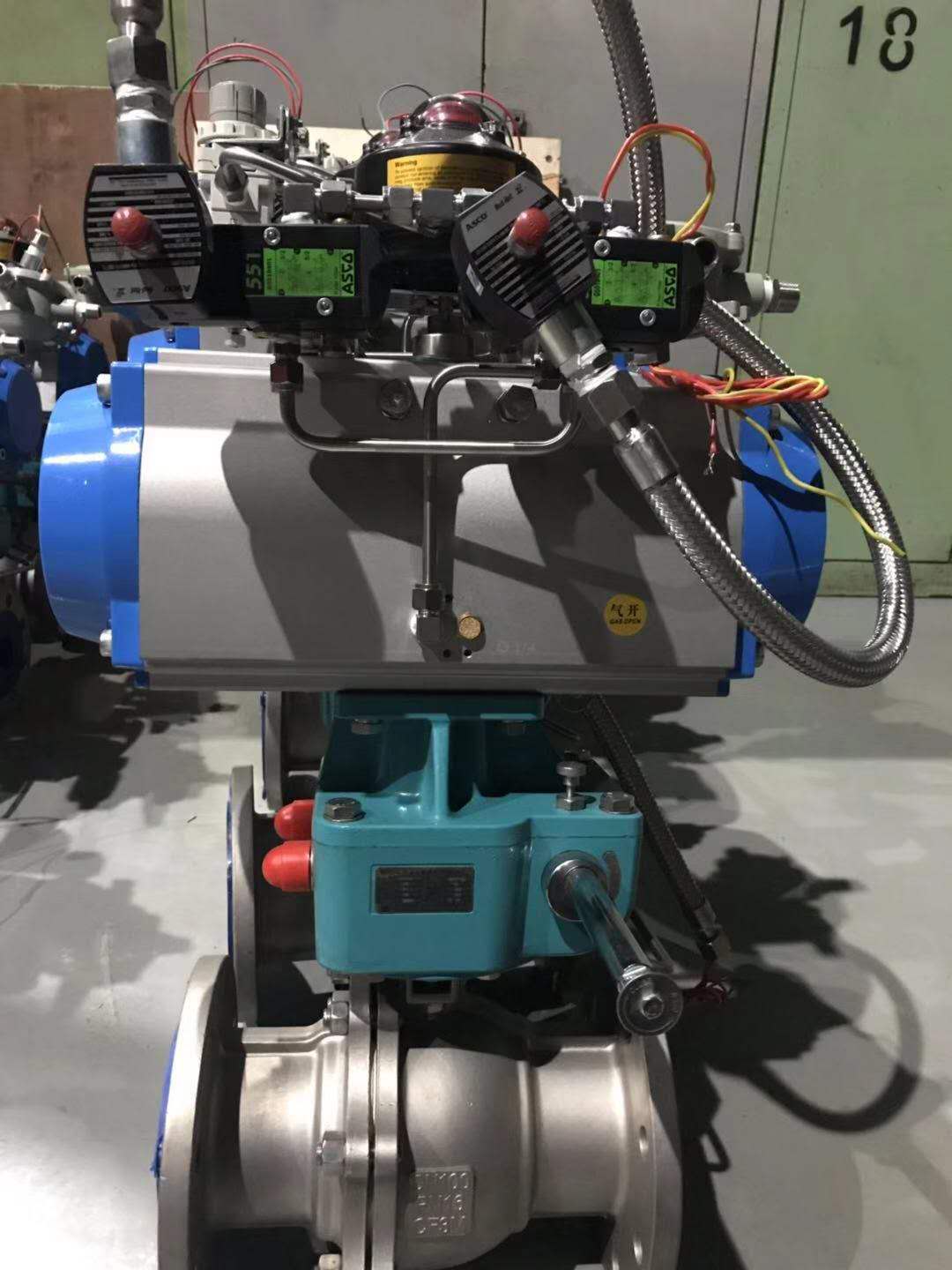

F2 系列浮动球阀-Floating Ball Valve的简单介绍F2 系列浮动球阀-Floating Ball Valve 提供手动、气动、电动等驱动方式F2 系列浮动球阀-Floating Ball Valve的详细信息主要设计特点-Main Designing Features

· 可调节的防火阀杆填料

Adjustable fire-safe stem packing

· 凸起的防火唇作为金属辅助密封阀座,符合API 607标准的防火要求,且可阻止流体对阀座内侧的冲蚀和阀座的冷流

The raised fire-lip acts as metal backup seat meeting API 607 through leakage requirements, and protects the seat from abrasion of flow and seat cold flow

· 防吹出阀杆

Anti-blow out stem

· 防静电装置

Anti-static device

· 可适合于任意方向的切断

Full rated bi-directional shut off

· 可选择的带锁手柄

Optional lockable handle

· 缠绕式垫片,防止外漏

Spiral wound gasket, prevent external leakage

· 可选择的操作:提供手动、气动、电动等驱动方式

A wide choice of handle, gear, electrical, pneumatic or hydraulic operators can be supplied.

· 符合NACE规范要求

All ball valves can be supplied in full compliance with NACE MR0175 Standard.

· 弹性阀座

Self-compensation seat

·低压时阀座位置 Seat Position at Low Pressure

低压时阀座弹性唇在装配预紧力的作用下,保证球与阀座间的可靠密封及阀门的最低的操作扭矩

An integral seat lip provides positive low pressure “bubble-tight” sealing of ball and seat. The assembly preload ensures constant surface load of ball to seat with minimum operating torque.

·高压时阀座位置 Seat Position at High Pressure

阀座唇在高压时的轻微变形使球与阀座全面接触,可恢复的弹性唇保证高、低压时的可靠密封性,并确保阀门较低的操作扭矩和更长的使用寿命。

The seat lip deflects slightly at higher pressure to ensure full seat-to-ball contact. The seat’s “memory-action” provides bubble-tight sealing at low and high pressure. The feature results in low torque and long life operation.

压力特性 低温极限

Pressure Ratings (PSIG) Low Temperature limits

主要零件标准材料规范 Standard Material Specification for Main Parts

|

我要询价

推荐产品

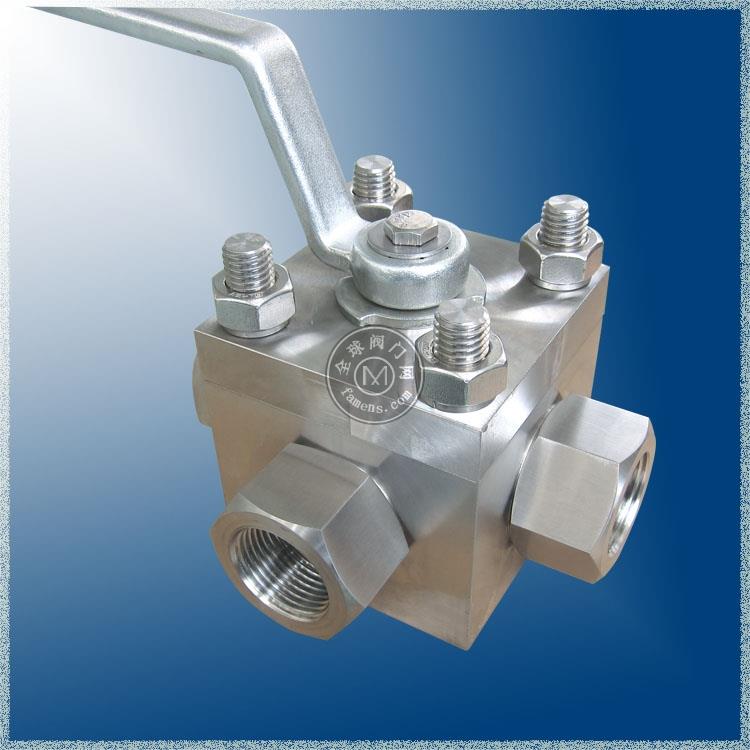

- Q14/15F内螺纹三通球阀

- 法兰三通球阀、T型三通球阀、L型三通球阀

- Q641F46-16P气动不锈钢衬氟球阀

- KP7015 数控球体磨床

- 高压L型换向球阀

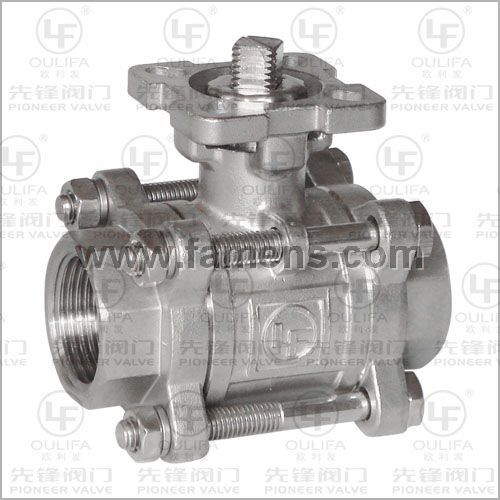

- 3PC高平台内螺纹球阀

- 水利球阀

- 上海北麦Q41F不锈钢球阀

- GEROYAL 电动塑料球阀PPH法兰连接软密封耐酸碱耐腐蚀阀门厂家

- 供应京牌热力球阀,京牌热力球阀Q967F,北京市阀门总厂股份有限公司热力球阀Q967F

- 冷冻机组 低温不锈钢球阀DQ41

- 法兰球阀

- 电动 全衬 半衬 耐磨 陶瓷 球阀

- 微型电动球阀

- 京牌 球阀

- AT气动球阀法兰Q641F-16铸钢不锈钢高温蒸汽快速切断开关三通V型

- 浮动球阀

- KP7025 数控球体磨床

- 北京市阀门总厂 气动球阀

- PVC气动球阀

- 美标球阀Q345Y

- 气动球阀

- 手动固定球阀

- Q941F电动球阀

19160434

19160434