Spring Plungers的简单介绍英寸螺纹可定制Spring Plungers的详细信息Without Thread Locker Install from the nose end without depressing the nose using a driver (sold separately). With a nose that is longer than a ball-nose, these provide a large bearing surface to handle side loads. Steel is strong and wear resistant. Zinc-plated steel bodies resist corrosion in wet environments. Black-oxide steel bodies resist corrosion in dry environments. 316 stainless steel is more corrosion resistant than 18-8 stainless steel and can be used in saltwater environments. 18-8 stainless steel is chemical resistant. Brass is corrosion resistant in wet environments; brass noses are soft to minimize marring. Plastic is chemical resistant and lightweight; acetal noses are extra soft to minimize marring soft surfaces such as aluminum. Spring plungers without thread locker are for use in soft material such as aluminum, in extreme temperatures, and on parts requiring frequent assembly and removal. Spring plungers with thread locker have a locking element that adds friction to resist loosening. Extended nose force is the force required to begin to depress the nose. Compressed nose force is the force required to depress the nose flush with the body. When using a plunger as a detent or stop, a lighter nose force with a shallower hole releases more easily, while a heavier force with a deeper hole holds more securely |

- Q14/15F内螺纹三通球阀

- 法兰三通球阀、T型三通球阀、L型三通球阀

- Q641F46-16P气动不锈钢衬氟球阀

- KP7015 数控球体磨床

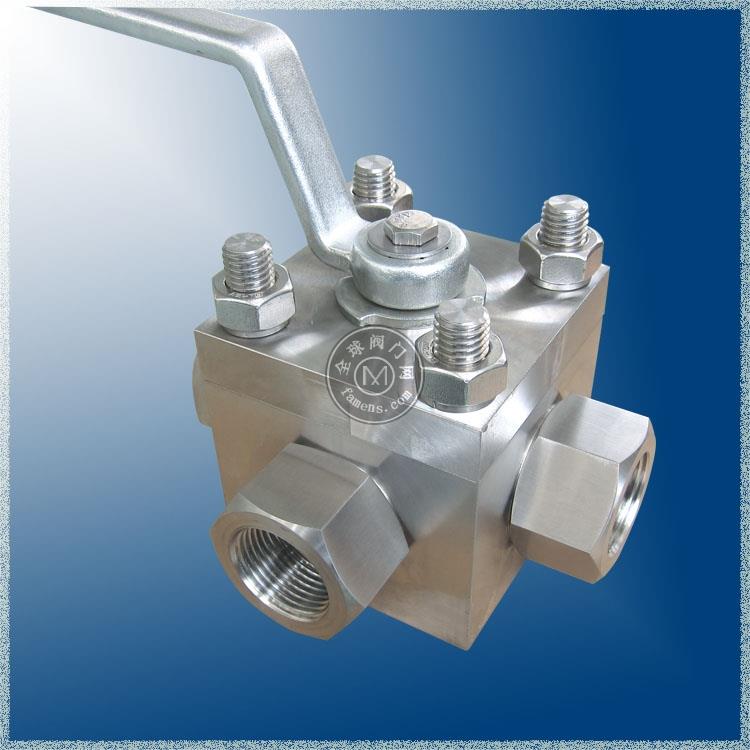

- 高压L型换向球阀

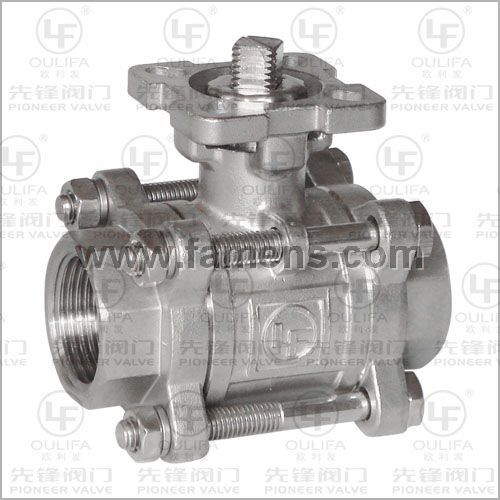

- 3PC高平台内螺纹球阀

- 水利球阀

- 上海北麦Q41F不锈钢球阀

- GEROYAL 电动塑料球阀PPH法兰连接软密封耐酸碱耐腐蚀阀门厂家

- 供应京牌热力球阀,京牌热力球阀Q967F,北京市阀门总厂股份有限公司热力球阀Q967F

- 冷冻机组 低温不锈钢球阀DQ41

- 法兰球阀

- 电动 全衬 半衬 耐磨 陶瓷 球阀

- 微型电动球阀

- 京牌 球阀

- AT气动球阀法兰Q641F-16铸钢不锈钢高温蒸汽快速切断开关三通V型

- 浮动球阀

- KP7025 数控球体磨床

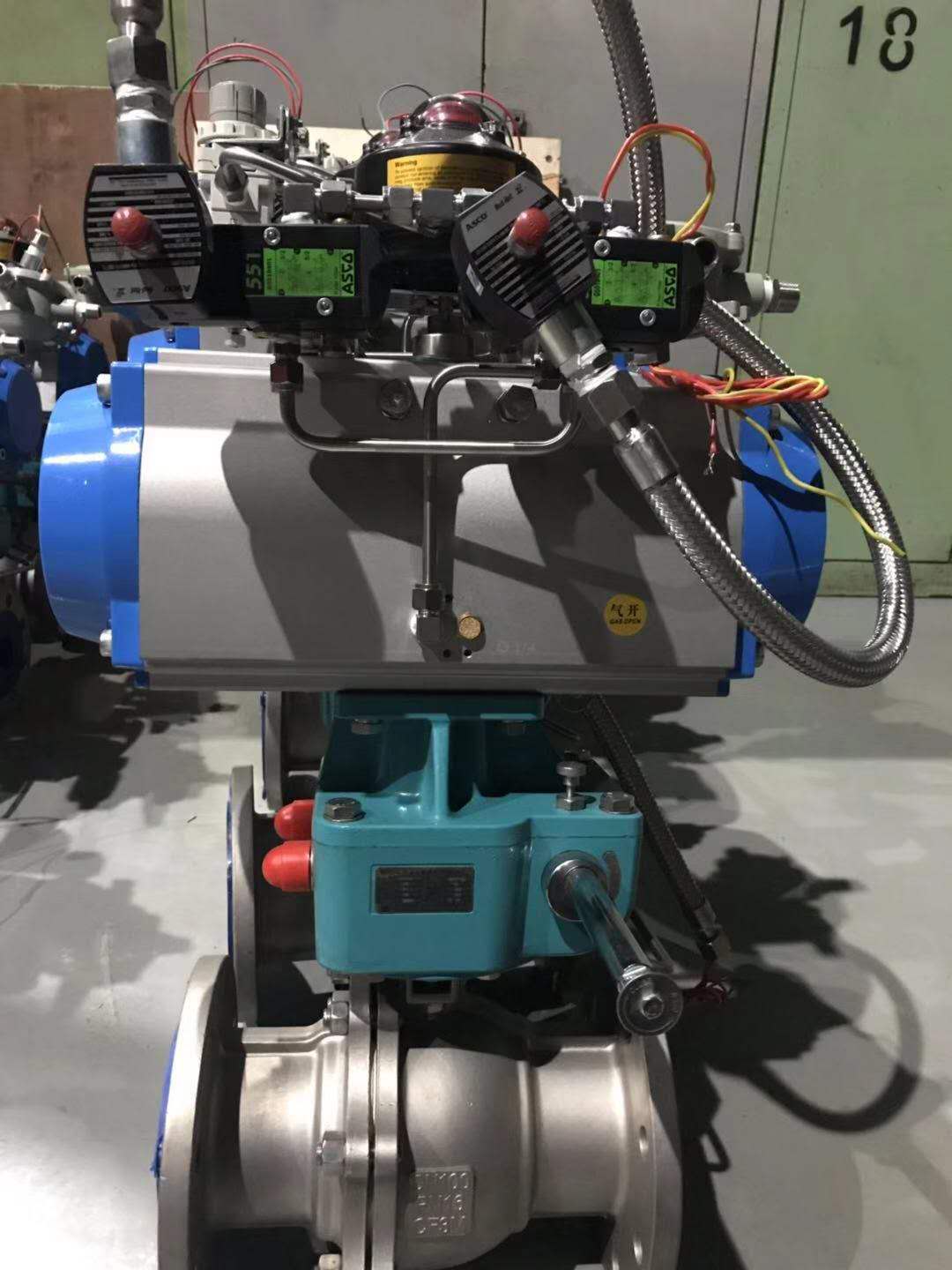

- 北京市阀门总厂 气动球阀

- PVC气动球阀

- 美标球阀Q345Y

- 气动球阀

- 手动固定球阀

- Q41F/PPL法兰浮动球阀

24376206

24376206